Accounting, Payroll and Custom Software

WinLedge Bill Of Materials

The Inventory module is a complete system for tracking the goods in your company, however if you are in the manufacturing business you might want a more detailed system for tracking the building of goods. That's where the WinLedge Bill of Materials comes in. This module is designed to augment the existing Inventory system and therefore the Inventory is required for use.

The Bill of Materials actually consists of two modules. The first is the Bill of Materials and the second is the Production Module. Both are included in the base price.

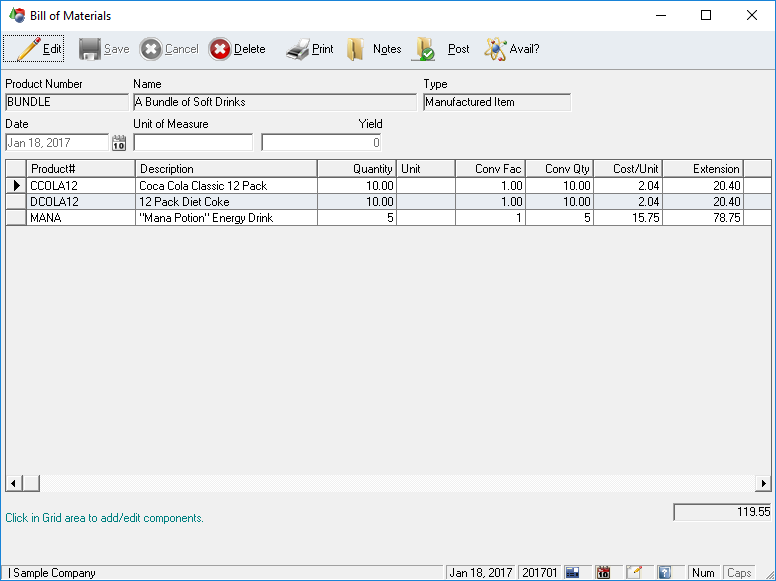

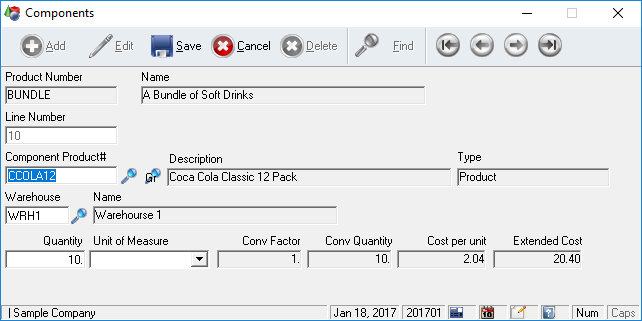

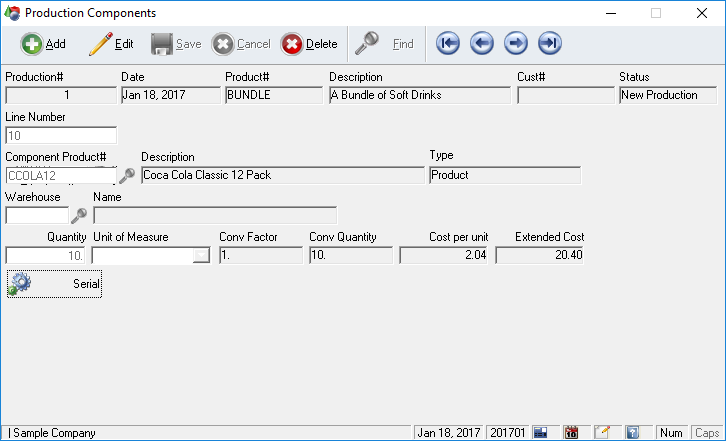

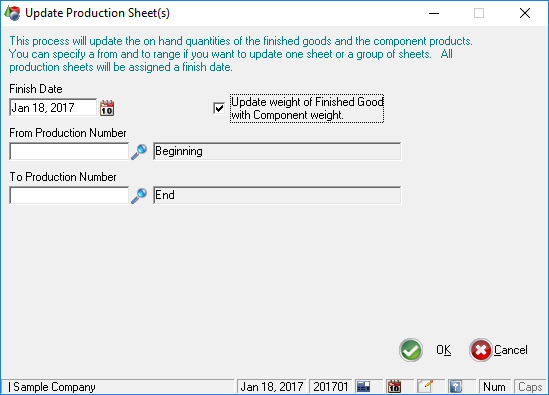

The Bill of Materials portion is where you define the structure of the finished good. Here you specify the components that make up the finished good, the yield values etc. Next you move to the actual production of the goods where you print off a production ticket to send back to the warehouse for building. You can then transfer all of this information over and bill in the usual manner. Of course, along the way there are lots of reports available to monitor the process.

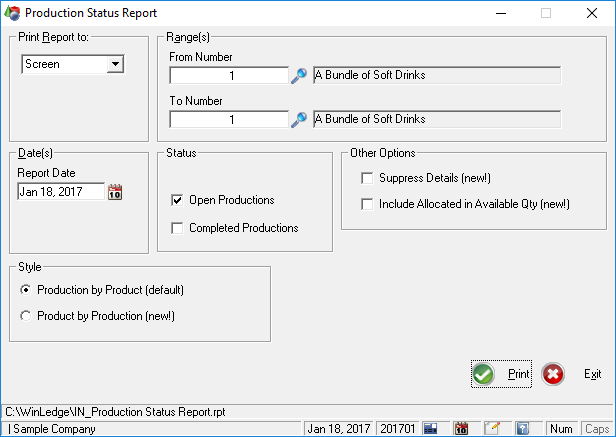

Compare the actual finish date to the estimated finish date and know your average days to fill a production. Key an eye on costs at the same time to ensure your productions stay profitable.

Where used reporting, available to build information, date ranges, product selections and much more will help you keep on top of busy production floors. Custom projects here include bar coding and ISO document revisions. Whatever your production needs, Classic can provide you with a complete solution.

Classic offers a comprehensive support program. For one low annual fee you receive, unlimited phone calls, emails, faxes and software updates. Premium "TeamViewer" and on-site support services are also available.

Extend your Inventory to track manufactured items. Add components, schedule a production and track the entire process with Winledge BOM.

Features Available...

- Unlimited number of components to make a finished good

- Components can also be finished goods (nested components)

- Yield values and Date of Bill of Material definition retained

- Unit of measure on finished goods

- Can draw components from multiple warehouses

- Extended notes file on every Bill of Material. Can record build instructions or any other information deemed pertinent to the build

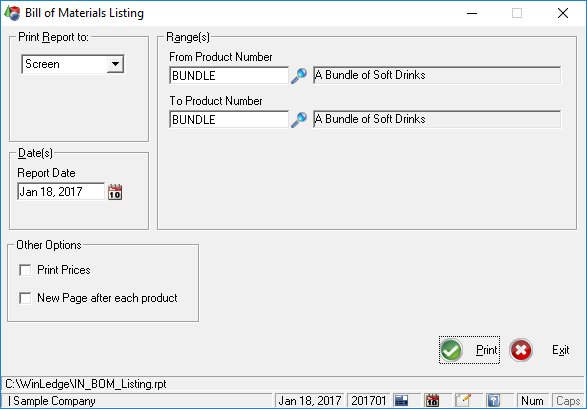

- Bill of Materials report, with or without pricing information

- Can edit BOM structure at any time and re-calculate costs instantly

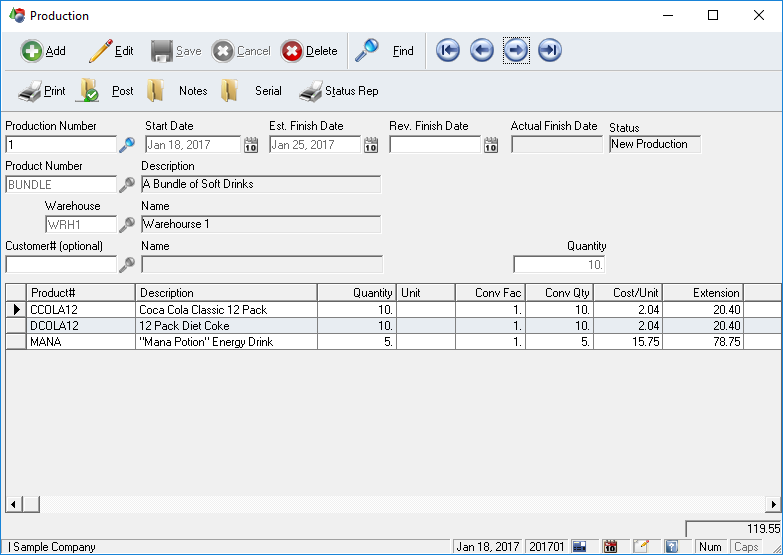

- 4 dates maintained on any production. Start Date, Estimated Finish Date, Revised Finish Date, Actual Finish Date

- Unique production numbers can be automatically generated by the system.

- Can specify number of units to produce and system will generate build list

- Build list can be edited to add additional items or revise existing build

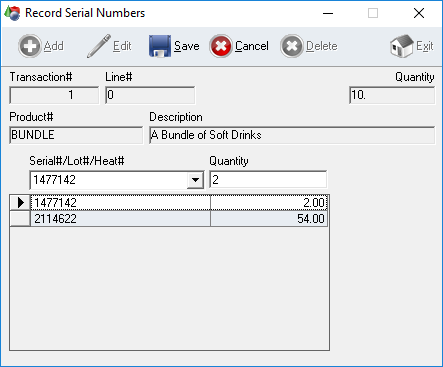

- Can record serial numbers on finished goods during/after production

- Notes available in production to specify build instructions. Can differ from BOM notes.

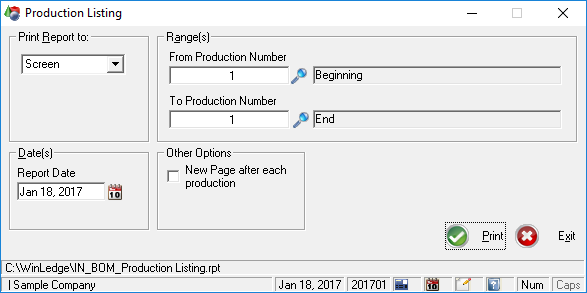

- Production reports can be printed for single or multiple productions.

- Variance from original BOM cost is calculated and printed.

- Reports can be printed to screen, printer or sent to more than 20 different file formats.